Renishaw ballbar is a great diagnostic tool to quickly and efficiently determine the overall condition of the machine tool.

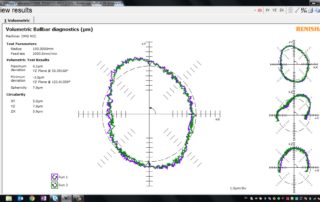

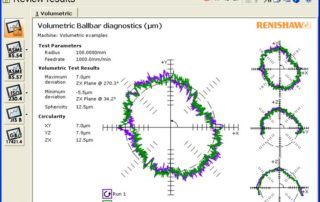

A three-axis machine tool has many degrees which can have a detrimental effect on the machines’ overall positioning and accuracy. Ballbar calibration is accurately measuring the actual circular path and comparing it with the program path. With this data we can determine the positioning accuracy of the machine. The ballbar test includes a few easy steps: set-up, data capture and analysis. A ballbar test will give you an instant report of your machine tool’s health, as well as an accurate visual representation of its travel through the axis in many planes. The test will illustrate geometrical issues, backlash, drive mismatches, reversal spikes scaling issues and much more.

CNC Tech uses this equipment extensively during the diagnostic process and repair to machine tool equipment. It is also used to set up and servo tune drives and parameters for optimum machine performance.

Ballbar equipment is also a great tool that CNC Tech uses as part of our preventative maintenance programs as we create a history of the condition of the machine and can use this to predict machine failures. Contact us today for your preventative maintenance program.

We offer a wide range of calibration services including:

- Geometrical calibration

- Laser Calibration

- Ballbar diagnostics

DOCUMENTS

Questions? Contact Us

Complete the form below and we’ll get back to you as soon as we can.