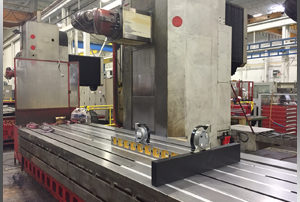

All CNC machines are subject to geometric inaccuracy over-time, as they wear and tear.

Numerous forces acting on your machine tool every day, from component weight to cutting loads, vibration and ambient climate factors can all affect your machine’s moving components. Displacement, straightness or linear axes errors can quickly lead to inaccuracy and quality of the product.

In order to meet specific tolerances, CNC Tech performs geometrical calibration at many of our customers’ businesses on an annual basis. We ensure that the machines are geometrically accurate. Geometrical calibration involves using precision electronic levels, granite squares, and straight edges to correct flatness, straightness, and perpendicularity of all axis back to OEM specs.

We recommend that machines are checked for levels annually in order to maintain your accuracy. Ask us about our preventative maintenance program.

We offer a wide range of calibration services including:

- Geometrical calibration

- Laser Calibration

- Ballbar diagnostics

Questions? Contact Us

Complete the form below and we’ll get back to you as soon as we can.